- Analytics & Modeling - Edge Analytics

- Analytics & Modeling - Predictive Analytics

- Functional Applications - Remote Monitoring & Control Systems

- Sensors - Pressure Sensors

- Sensors - Vibration Sensors

- Utilities

- Maintenance

- Predictive Maintenance

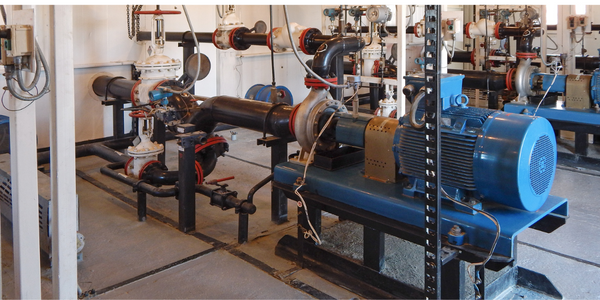

The Condensate Cooling Water (CCW) pump, one of the critical pumps in maintaining steadystate operations, is a horizontal vane pump operating at up to 1650 m3/hr with a discharge pressure of 9 MPa (62 psi) at 986 rpm. Each day this pump is offline costs the plant $250,000 in lost revenue and each failure costs tens of thousands of dollars to execute an unplanned repair. Thus, Larsen & Toubro (L&T) really needed a predictive maintenance solution to detect faults at an early stage and provide a reliable prediction of Remaining Useful Life (RUL)

We proposed our RotationLF system under which we installed around 24 wireless sensors as a part of a pilot project on air compressors, ACW and CCW Pumps, and Fans.

The specific placement of the VibrationLF sensors are selected to monitor:

1) Non-drive side bearing, electric motor

2) Drive side bearing, electric motor

3) Drive side Bearing, pump

4) Non-drive side bearing, pump

Once installed, strong battery-powered wireless sensors started monitoring pump and motors and sending data to our SaaS-based platform through an encrypted & secured network using Edge and Cloud computing. As data was received, RotationLF platform worked on data analysis using highly sophisticated algorithms.

Approximately six weeks after the sensors were installed, the AI alerted L&T that a vane fault had been detected on the pump, causing cavitation. The fault frequency depicted in the system is indicative of an early-stage failure.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.