- Analytics & Modeling - Big Data Analytics

- Application Infrastructure & Middleware - API Integration & Management

- Functional Applications - Remote Monitoring & Control Systems

- Networks & Connectivity - Gateways

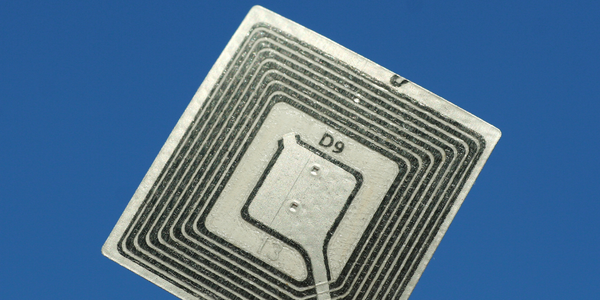

- Networks & Connectivity - RFID

- Platform as a Service (PaaS) - Application Development Platforms

- Sensors - RFID Readers

- Wearables - Tags & Patches

- Apparel

- Discrete Manufacturing

- Track & Trace of Assets

At any given time, the textile company’s manufacturing facility has up to 2,000 textile carts in use. These carts are pushed from room to room, carrying materials or semi-finished products. Previously, a paper with a hand-written description was attached to each cart. This traditional method of processing made product tracking extremely difficult. Additionally, making sure that every cart of materials or semi-finished products went to its correct processing work station was also a problem. Therefore, the company desired an intelligent solution for tracking assets at their factories. They also wanted a solution that would help them collect process data so they could improve their manufacturing efficiency.

Under Advantech’s WISE-PaaS Alliance program, the textile company deployed a cart tracking system at their facility. RFID tags were attached to each cart, and an RFID reader antenna was attached to every machine or piece of equipment. Now when a cart approaches, the RFID reader gets the ID of this cart from its tag, and transmits the data to an ARK-1123 data gateway. Using its WISE-PaaS/RMM remote data and device monitoring and management software, the gateway ensures data transmission and device security. WISE-PaaS also provided RESTful APIs for easy integration with MES to enabled electronic production records. And Microsoft Azure provides for IoT big data computing and analytics. Most importantly, WISE-PaaS offers easy access across programming platforms and can be integrated with existing management solutions to improve products/services and business intelligence.

Case Study missing?

Start adding your own!

Register with your work email and create a new case study profile for your business.

Related Case Studies.